Izod Sample Evaluation

by Optical Comparator @ 50X Magnification

Riverview customers who take advantage of our Notched Specimen Analysis enjoy two benefits: [1] - they have a third party determination and certificate to present as evidenced during any assessment, and [2] - have a report that not only shows samples to be in compliance but also shows how each sample compares to the other, spreadsheets can be generated to show trends and ensure that the sample process remains effective and provides the best izod results whether providing In-house data or participation in a Round-Robin environment.

ASTM D256 (paragraph 8.6)

Requires that: the specimen notch produced by EACH cutter will be examined after every 500th notching operations or less frequently if experience shows this to be acceptable. The notch in the specimen, made of the material to be tested, shall be inspected and verified. Each type material being notched must be inspected and verified at that time.

Customers are instructed to send in batches of five (5) samples, 3 will be used for the analysis and the other two will be back-up. DO NOT use a material that is "Heat Sensitive". Since measurements & inspection are made using an Optical Comparator at 50X magnification, heat from the projection lamp also is magnified. In some cases, materials tended to soften, melt and distort during the measurement process before all readings could be obtained.

Visually inspect each samples notched area, ensure the condition of the notched edges have been checked for defects such as burrs, pits, nicks.

Good Lines - Clean, crisp lines are critical to obtaining an accurate measurement, blurred and/or obstructed lines cannot be accurately measured, it also indicates that the customers process is leaving behind material during the sample preparation process.

Material Left - remaining material should be removed by taking a rubber band or brush and running it thru the notch, Riverview is not allowed to alter samples, we do not file or trim samples, they are to be tested as is from customer.

The Samples are measured against dimensional specifications outlined in the appropriate ASTM or ISO method, utilizing NIST traceable standards and equipment. A "Certificate of Verification" with "As Found" data is issued showing results over-all and a comparison form showing how each individual sample compares to othesr in batch. Riverview is a small company that customizes its service to the customer. I am proud to say that our customers love our certificates. We make them easy to read and understand, packing them with as much information as possible and ensuring they conform to ANSI/ISO/IEC 17025:2005(E), ANSI/NCSL Z540-1-1994 and A2LA requirements.

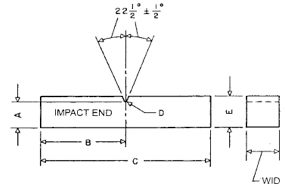

ASTM Izod Notched Sample

per ASTM D256 Appendix X1

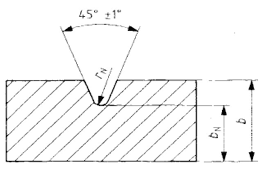

ISO Izod Notched Sample

per ISO 179-1 & ISO 180

We Accept