Hardness Services

- Durometer Calibration per ASTM D2240

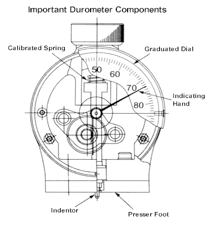

Upon receipt, the durometer's dimensional characteristics are measured, using 50X maginification the indentor extension is verified and a visual inspection is performed. As found readings are taken, adjustments made if necessary. The internal mechanism is checked for defects such as ( loose or missing parts, nicks, burrs, that may interfere with the action ). Spring loading requirements are verified by "Direct Loading" procedure on Riverview's duro-calibrator. The unit is cleaned, As Left readings taken and final conditions are noted on the calibration report.

- 7.1 Indentor (extension, angle, radius)

- 7.2 Indentor Display Adjustment

- 7.5 Spring Calibration (Direct Loading)

- 7.8 Reference Test or Spring Block if present

- Indentor Replacement (if required)

Note: Any repair work or part replacement is first authorized by the customer.

Typical Types Serviced

![]()

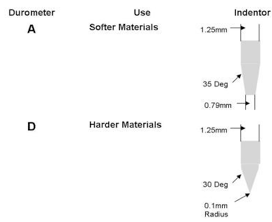

- Indentor Inspection "A&D" per ASTM D2240

Measured by Optical Comparator using 50x Magnification

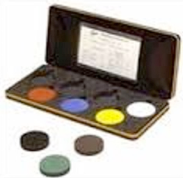

- Shore "A" Rubber Test Blocks per ASTM D2240

The rubber reference block(s) provided for verifying durometer operation and state of calibration are not to be relied upon as calibration standards. The use of metal reference blocks is no longer recommended.

(A 3 day round-robin type study is performed)

- Send In Order Form

Please use the Form provided when sending anything in for service. The more information you provide is helpful in Riverview providing you the most efficient and accurate service.

- Service Notices

We also track your equipment, 30 days prior to due dates we send out "Service Notices" to our customers.

We Accept